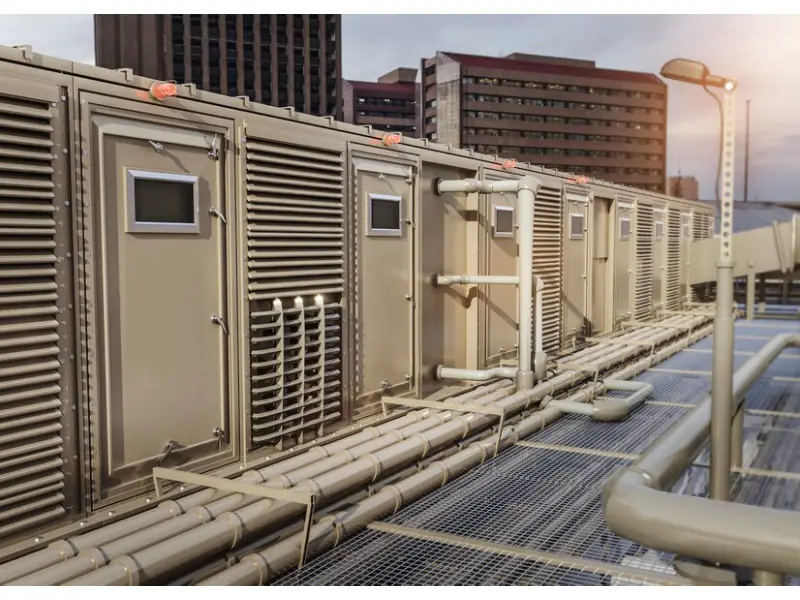

A package hot air generator is a compact, pre-assembled unit that integrates all the necessary components for generating hot air, making it ideal for various industrial applications. The key features that make package hot air generators a valuable addition to industrial environments include their efficiency, reliability, and ease of installation. These units are typically designed with advanced combustion systems that maximize fuel utilization, reducing waste and lowering emissions. Furthermore, they often come equipped with high-efficiency burners and heat exchangers that ensure optimal thermal performance. One of the standout features of package hot air generators is their modular design, which allows for easy integration into existing systems without the need for extensive modifications.

How a Package Hot Air Generator Boosts Energy Efficiency and Cost Savings?

One of the most compelling reasons to choose a package hot air generator for industrial applications is its ability to significantly boost energy efficiency and cost savings. Traditional heating systems, such as furnaces or boilers, often suffer from high energy consumption due to inefficient combustion processes, heat loss, and poor thermal management. In contrast, package hot air generators are designed to optimize every aspect of the heat generation process. They utilize advanced combustion technology that ensures complete fuel burn, thereby maximizing energy output and minimizing waste. This results in lower fuel consumption and reduced operating costs. Additionally, many package hot air generators feature heat recovery systems that capture and reuse waste heat, further enhancing efficiency and reducing energy costs. The integration of sophisticated control systems also plays a crucial role in optimizing energy use by allowing operators to precisely regulate the temperature and airflow according to the specific needs of their processes.

Step-by-Step Guide to Installing a Package Hot Air Generator for Optimal Performance

Installing a package hot air generator for optimal performance involves a series of critical steps that ensure the system operates efficiently and safely. The first step is to conduct a thorough site assessment to determine the most suitable location for the generator. This includes considering factors such as space availability, proximity to fuel supply lines, ventilation requirements, and access for maintenance and repairs. Once the location is determined, the next step is to prepare the site by ensuring it meets all safety and regulatory standards. This may involve installing appropriate ventilation systems, securing the necessary permits, and laying down a stable foundation to support the weight of the generator. After the site is prepared, the package hot air generator is carefully positioned and anchored to prevent movement or vibration during operation. The installation team then connects the fuel supply lines, electrical connections, and control systems, ensuring that all connections are secure and compliant with safety standards. Once the generator is installed, it undergoes a series of tests to verify that it is functioning correctly and safely.

The Top Benefits of Choosing a Package Hot Air Generator Over Traditional Heating Systems

There are numerous advantages to choosing a package hot air generator over traditional heating systems, making it a preferred choice for many industrial applications. One of the primary benefits is the enhanced energy efficiency that package hot air generators offer. Unlike traditional systems, which often suffer from significant heat loss and inefficient fuel consumption, package hot air generators are designed to maximize energy output and minimize waste. This leads to lower fuel consumption and reduced energy costs, providing substantial savings over the long term. Additionally, package hot air generators offer superior flexibility and ease of installation. Their compact, modular design allows for quick and straightforward integration into existing systems, minimizing downtime and disruption to operations. Another significant advantage is their reliability. Package hot air generators are built to withstand the rigors of industrial use, featuring robust construction materials and components that ensure long-lasting performance. They are also equipped with advanced control systems that allow for precise temperature regulation, contributing to improved process control and consistency.

Exploring the Latest Technological Advancements in Package Hot Air Generator Design

The design and functionality of package hot air generators have evolved significantly in recent years, thanks to technological advancements that have enhanced their efficiency, reliability, and ease of use. One of the most notable advancements is the development of high-efficiency burners and heat exchangers that maximize thermal performance and minimize energy consumption. These components are designed to optimize combustion processes, ensuring complete fuel burn and reducing waste. Additionally, many modern package hot air generators are equipped with sophisticated control systems that allow for precise monitoring and regulation of temperature and airflow. These control systems often feature advanced sensors and automation capabilities that enable real-time adjustments based on changing operational conditions, further enhancing efficiency and reducing energy costs. Another significant advancement is the incorporation of heat recovery systems that capture and reuse waste heat, contributing to improved energy efficiency and cost savings.

Why a Package Hot Air Generator is the Ideal Choice for Consistent, Reliable Heat?

For industries that require a constant and reliable supply of heat, package hot air generators offer an ideal solution. These generators are designed to deliver consistent heat output, regardless of external conditions, ensuring that critical processes are not disrupted. This reliability is achieved through the use of high-quality components and advanced engineering that minimizes the risk of breakdowns and malfunctions. Package hot air generators are built to withstand the harsh conditions of industrial environments, featuring robust construction materials that resist corrosion and wear. Additionally, they are equipped with advanced control systems that allow for precise temperature regulation, ensuring that the desired temperature is maintained at all times.

Maintenance Tips for Maximizing the Lifespan of Your Package Hot Air Generator

Regular maintenance is essential for maximizing the lifespan and performance of a package hot air generator. One of the most important maintenance tasks is to regularly inspect and clean the burner and heat exchanger to prevent the buildup of soot, dirt, and other contaminants that can reduce efficiency and cause damage. It is also crucial to check the fuel supply lines and connections for leaks or blockages, as these can lead to incomplete combustion and increased energy consumption. The control system should be calibrated regularly to ensure accurate temperature regulation and optimal performance. Additionally, the generator’s filters should be inspected and replaced as needed to prevent airflow restrictions that can reduce efficiency and cause overheating.

Comparing Different Types of Package Hot Air Generators to Find the Perfect Fit

When selecting a package hot air generator, it is essential to consider the different types available to find the one that best meets your specific needs. The most common types of package hot air generators include oil-fired, gas-fired, and electric models, each with its unique advantages and disadvantages. Oil-fired hot air generators are known for their high efficiency and ability to deliver a large volume of hot air, making them ideal for heavy-duty industrial applications. However, they require a reliable supply of oil and may have higher operating costs due to fuel prices. Gas-fired hot air generators are typically more cost-effective and environmentally friendly, as they produce fewer emissions and have lower fuel costs.

Conclusion

Package hot air generators represent a versatile and efficient heating solution for a wide range of industrial applications. With their advanced features, energy efficiency, and ease of installation, these generators offer a reliable and cost-effective way to meet the heating needs of various industries. By understanding the key features, benefits, installation process, and maintenance requirements, businesses can make informed decisions about their use and maximize their return on investment. Whether you are looking to enhance energy efficiency, reduce operating costs, or improve environmental compliance, a package hot air generator provides a compelling solution that delivers consistent, reliable heat while meeting the high demands of industrial applications.

Resouece URL:

https://en.wikipedia.org/wiki/Hot_air_engine

https://www.thermodyneboilers.com/intech-three-pass-internal-furnace-packaged-type-boilers/

Introducing Kyriakos Loretta, a nomadic wordsmith navigating the ever-shifting cities of the United States. This prolific author has penned captivating books that reflect a passion for storytelling that knows no boundaries. Beyond the written realm, Kyriakos collaborates with magazines and news channels, weaving narratives that mirror the dynamism of the diverse American urban landscape.