Custom CNC machining parts manufacturing has become a cornerstone of the automotive industry, driving innovation, efficiency, and quality in vehicle production. CNC, or Computer Numerical Control, machining utilizes advanced technology to create precise and complex parts that meet the exact specifications required by automotive engineers and designers. This manufacturing technique has transformed the automotive landscape, allowing for the production of lightweight, durable components that contribute to improved performance and fuel efficiency. As the automotive industry evolves to meet the challenges of modern transportation, including sustainability and the integration of smart technology, custom CNC machining plays a vital role in ensuring that manufacturers can meet these demands. This article delves into the various aspects of custom CNC machining parts manufacturing in the automotive sector, examining its impact on vehicle performance, production efficiency, quality control, design innovation, cost benefits, and future trends.

Custom CNC Machining Parts Manufacturing In The Automotive Sector

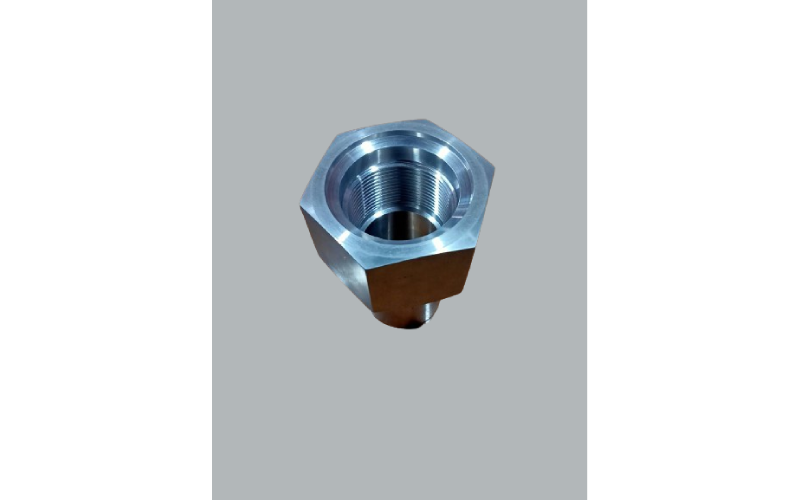

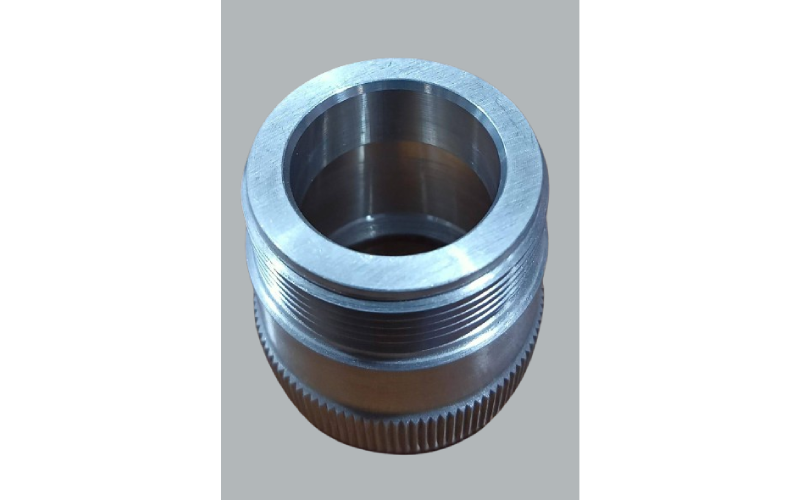

Custom CNC machining parts manufacturing has revolutionized the automotive sector by enabling the production of high-precision components essential for modern vehicles. This process involves using computer-controlled machines to shape and fabricate parts from various materials, including metals, plastics, and composites. Automotive manufacturers rely heavily on CNC machining due to its ability to produce intricate designs with tight tolerances, which are crucial for maintaining performance and safety standards. From engine components and transmission parts to intricate interior features and body panels, custom CNC machining is integral to nearly every aspect of vehicle production. The flexibility of CNC machining allows for rapid prototyping and mass production, giving manufacturers the agility to adapt to changing market demands. Moreover, as vehicles become more complex with the introduction of electric and autonomous technologies, the need for specialized, high-quality components continues to grow, further solidifying the role of custom CNC machining in the automotive industry.

Custom CNC Machining Parts Manufacturing In Enhancing Vehicle Performance

Custom CNC machining parts manufacturing plays a critical role in enhancing vehicle performance by producing high-quality components that contribute to the overall efficiency and effectiveness of automotive systems. Precision-engineered parts, such as engine blocks, pistons, and transmission components, directly impact a vehicle’s power output, fuel efficiency, and reliability. CNC machining allows manufacturers to create lightweight yet strong parts that reduce overall vehicle weight, leading to improved fuel economy and handling. The ability to produce complex geometries also enables the development of advanced features like optimized airflow in engine components, which enhances combustion efficiency and performance. Furthermore, custom CNC machining supports the integration of innovative technologies in vehicles, such as adaptive suspension systems and regenerative braking components. By ensuring that all parts are manufactured to exact specifications, CNC machining helps to minimize friction and wear, resulting in a longer lifespan for critical components and an overall increase in vehicle performance.

Custom CNC Machining Parts Manufacturing And Its Impact On Production Efficiency

The impact of custom CNC machining parts manufacturing on production efficiency in the automotive industry cannot be overstated. Traditional manufacturing methods often involve labor-intensive processes that can be time-consuming and prone to human error. In contrast, CNC machining automates many of these processes, allowing for faster production cycles and increased output without compromising quality. This efficiency is especially vital in the automotive industry, where time-to-market is crucial for remaining competitive. The ability to produce multiple parts simultaneously and with minimal downtime significantly reduces lead times, allowing manufacturers to respond swiftly to changing consumer demands and market trends. Additionally, CNC machining’s flexibility enables the rapid adaptation of production lines to accommodate new designs or variations, further enhancing overall efficiency. The use of advanced software and robotics in CNC machining also contributes to streamlined operations, reducing waste and lowering production costs. Overall, custom CNC machining parts manufacturing not only boosts productivity but also allows automotive manufacturers to maintain a high level of quality and consistency in their products.

Quality Control In Custom CNC Machining Parts Manufacturing For Automotive Applications

Quality control is a fundamental aspect of custom CNC machining parts manufacturing, particularly in the automotive industry, where safety and reliability are paramount. The precision offered by CNC machining is complemented by rigorous quality control measures designed to ensure that every part produced meets strict industry standards and specifications. Manufacturers employ various inspection techniques, including automated measurement systems and laser scanning, to verify the dimensions and tolerances of machined parts. Additionally, many automotive companies implement a comprehensive quality management system that encompasses every stage of the production process, from design validation to final inspections. This proactive approach to quality assurance helps to identify and address potential issues before they reach the assembly line, minimizing the risk of defects and recalls. By adhering to international quality standards such as ISO/TS 16949, which is specifically designed for the automotive sector, custom CNC machining parts manufacturers can ensure the delivery of reliable, high-performance components that contribute to the overall safety and integrity of vehicles.

Custom CNC Machining Parts Manufacturing And Its Contribution To Design Innovation

Custom CNC machining parts manufacturing significantly contributes to design innovation in the automotive industry by enabling designers and engineers to explore new concepts and ideas without the constraints of traditional manufacturing methods. The flexibility and precision of CNC machining allow for the creation of complex shapes and intricate details that were once deemed impossible or too costly to produce. This capability fosters a culture of innovation, encouraging automotive manufacturers to push the boundaries of design in pursuit of improved functionality and aesthetics. For instance, CNC machining can produce lightweight structural components that enhance vehicle performance while maintaining safety standards. Additionally, the rapid prototyping capabilities of CNC machining enable manufacturers to test and refine their designs quickly, facilitating iterative improvements and reducing the time it takes to bring new products to market. As the automotive industry shifts towards electric and autonomous vehicles, the need for innovative designs that optimize performance and user experience will only grow, making custom CNC machining an essential tool for driving future advancements in automotive technology.

Custom CNC Machining Parts Manufacturing For Automotive Companies

Custom CNC machining parts manufacturing offers significant cost benefits for automotive companies, making it a preferred choice for producing critical components. While the initial setup costs for CNC machines and tooling can be high, the long-term savings achieved through increased efficiency and reduced labor costs often outweigh these expenses. The automated nature of CNC machining minimizes the need for manual labor, lowering wage costs and the potential for human error. Furthermore, the precision of CNC machining reduces material waste by ensuring that parts are cut to exact specifications, maximizing the yield from raw materials. Additionally, the ability to produce high volumes of components in a shorter timeframe allows manufacturers to benefit from economies of scale, driving down per-unit costs. Custom CNC machining also supports just-in-time manufacturing practices, enabling automotive companies to maintain lower inventory levels and reduce storage costs. By leveraging these cost benefits, automotive manufacturers can enhance their profitability while maintaining competitive pricing in the market.

Custom CNC Machining Parts Manufacturing Within Automotive Industry

The future of custom CNC machining parts manufacturing within the automotive industry is poised for significant advancements driven by technological innovations and evolving market demands. One key trend is the increasing integration of automation and robotics into CNC machining processes, which will enhance production speed and accuracy while reducing labor costs. Additionally, the rise of Industry 4.0 and the Internet of Things (IoT) will enable manufacturers to implement smart manufacturing practices, allowing for real-time monitoring and data analysis to optimize production efficiency and quality control. The growing focus on sustainability is also influencing custom CNC machining, with manufacturers exploring eco-friendly materials and processes to reduce their environmental footprint. Moreover, as electric and autonomous vehicles become more prevalent, the demand for specialized components that support these technologies will drive further innovation in CNC machining techniques. Overall, the future of custom CNC machining parts manufacturing in the automotive industry will be characterized by increased efficiency, sustainability, and adaptability, positioning it as a crucial player in shaping the next generation of vehicles.

Conclusion

In conclusion, custom CNC machining parts manufacturing is an integral component of the automotive industry, providing essential support across various facets of vehicle production. From enhancing vehicle performance and improving production efficiency to ensuring quality control and fostering design innovation, CNC machining plays a vital role in meeting the challenges of modern automotive manufacturing. The cost benefits associated with CNC machining further solidify its position as a preferred method for producing high-quality automotive components. As the industry continues to evolve in response to emerging technologies and changing consumer demands, custom CNC machining will remain at the forefront of innovation, driving advancements in vehicle design and production processes. By embracing the capabilities of custom CNC machining parts manufacturing, automotive companies can enhance their competitiveness and position themselves for success in the rapidly changing automotive landscape.

Introducing Kyriakos Loretta, a nomadic wordsmith navigating the ever-shifting cities of the United States. This prolific author has penned captivating books that reflect a passion for storytelling that knows no boundaries. Beyond the written realm, Kyriakos collaborates with magazines and news channels, weaving narratives that mirror the dynamism of the diverse American urban landscape.